SPOTTING PRESSES FOR ASSEMBLY, ADJUSTMENT, CHECKING AND REPAIR OF SMALL MOULDS AND DIES

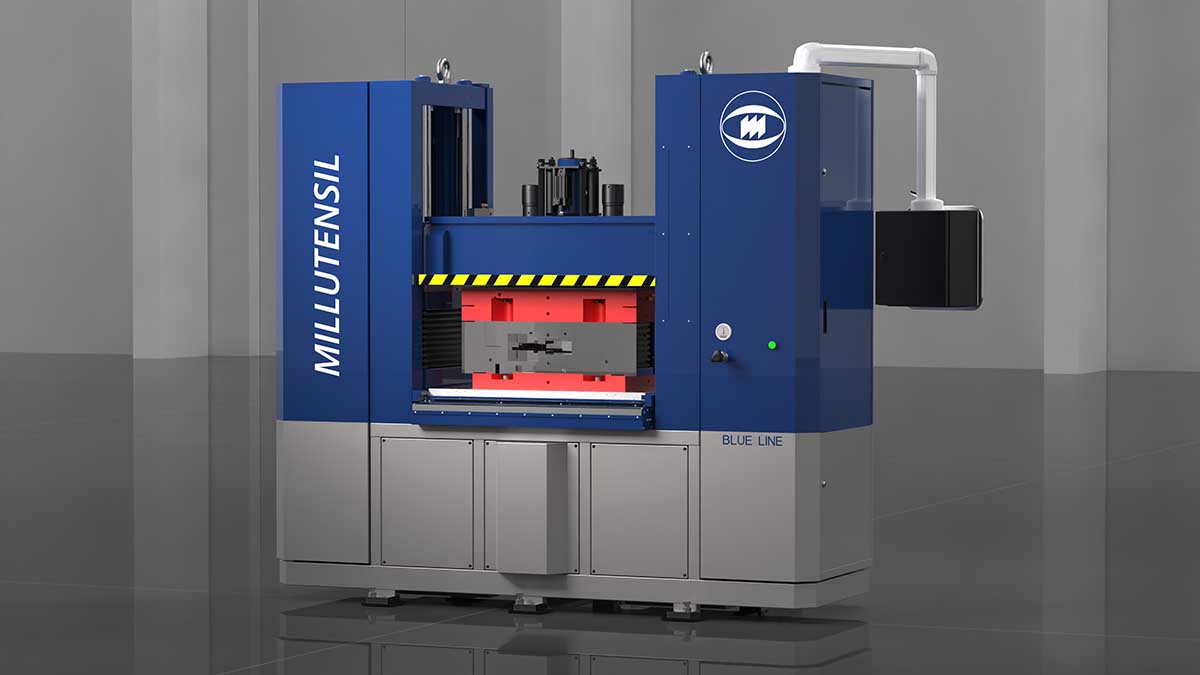

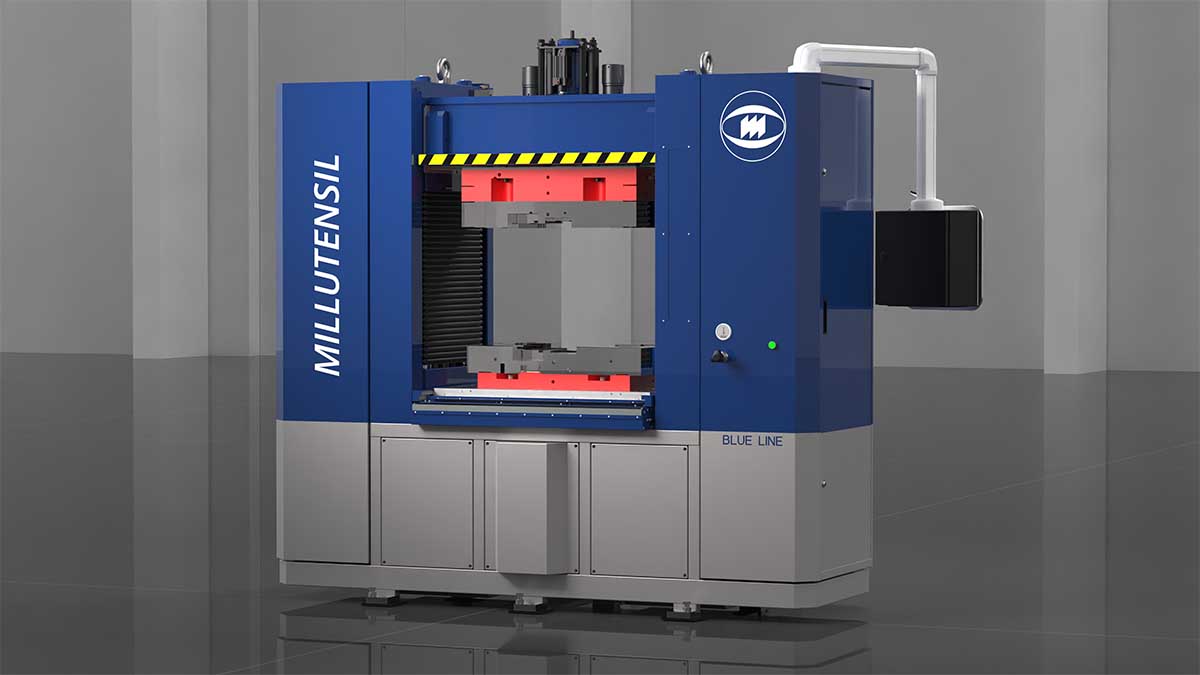

BV 25P / 26C

The press is used for splitting, adjusting, maintenance and try-out operations on dies and moulds (thermoplastics, die casting, thermosetting, rubber and blanking).

The BV 25P and 26C are suitable for small-sized moulds.

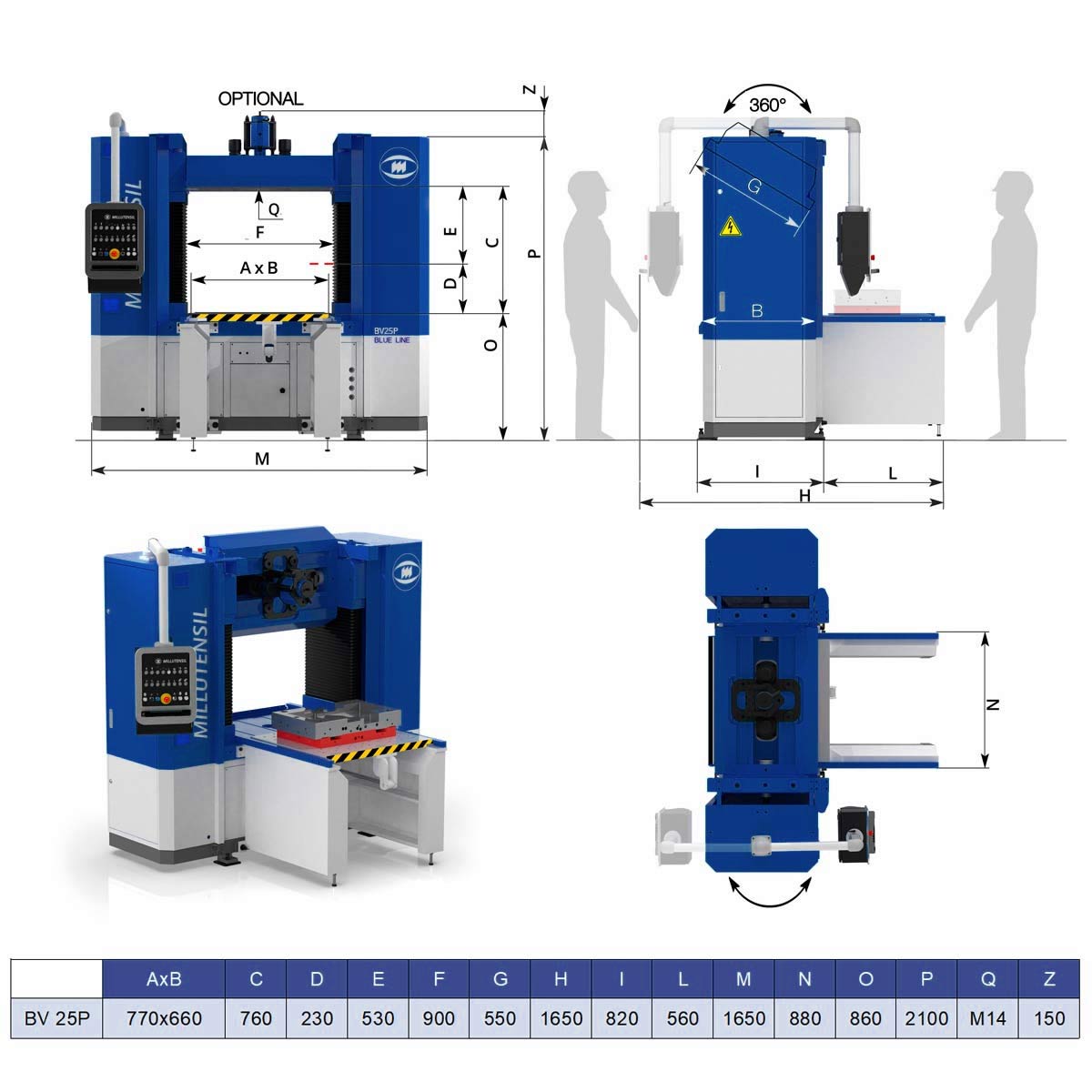

Platen dimensions available are 770×660 mm (BV 25P) or 980 ×750 mm (BV 26C). The very sturdy structure consists of a welded and normalized steel basement and cast iron baseplate. Hydraulic system is controlled by electronic servo proportional valves.

Both models are equipped with a control panel with manual buttons and user-friendly graphic icons.

BV 25P

BV 26C

All components are purchased from well-known manufacturers, such as for example: hydraulic system Bosch-Rexroth, Hawe; electrical system Siemens, Schneider Elektrik, Phoenix Contact, Weidmüller. This guarantees a general good functionality of the press, and a quick procurement all over the world.

EC Declaration of Conformity and compliance with safety provisions in accordance with the current EC standards.

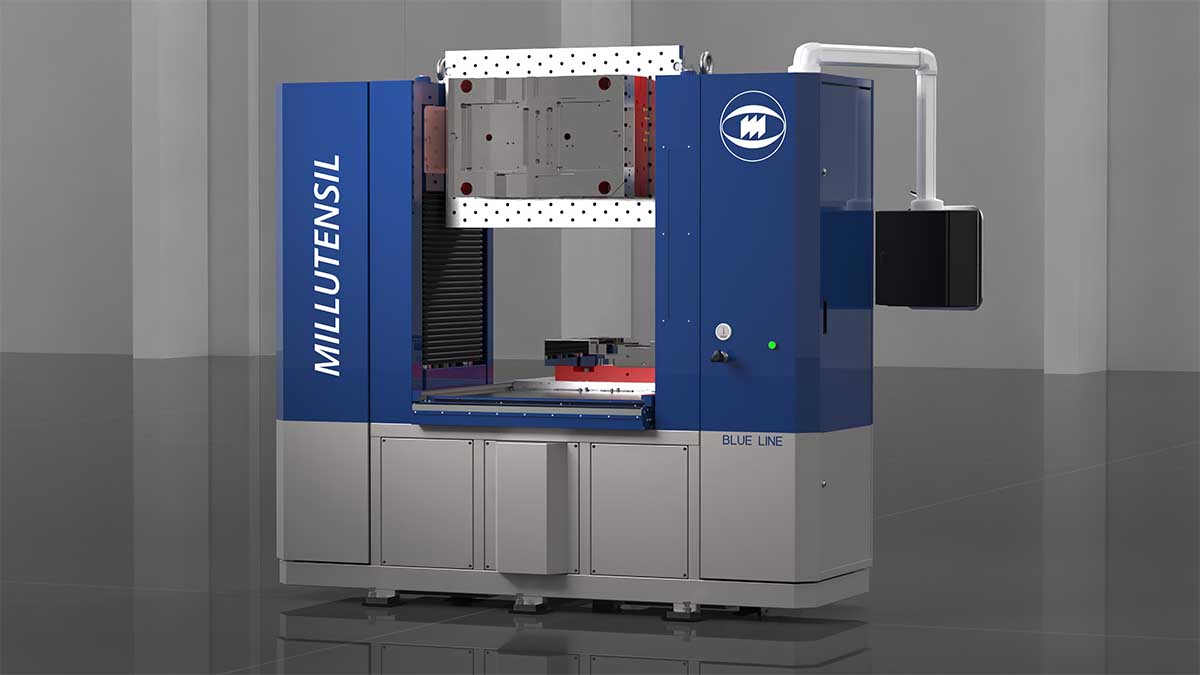

PLATENS MOVEMENTS

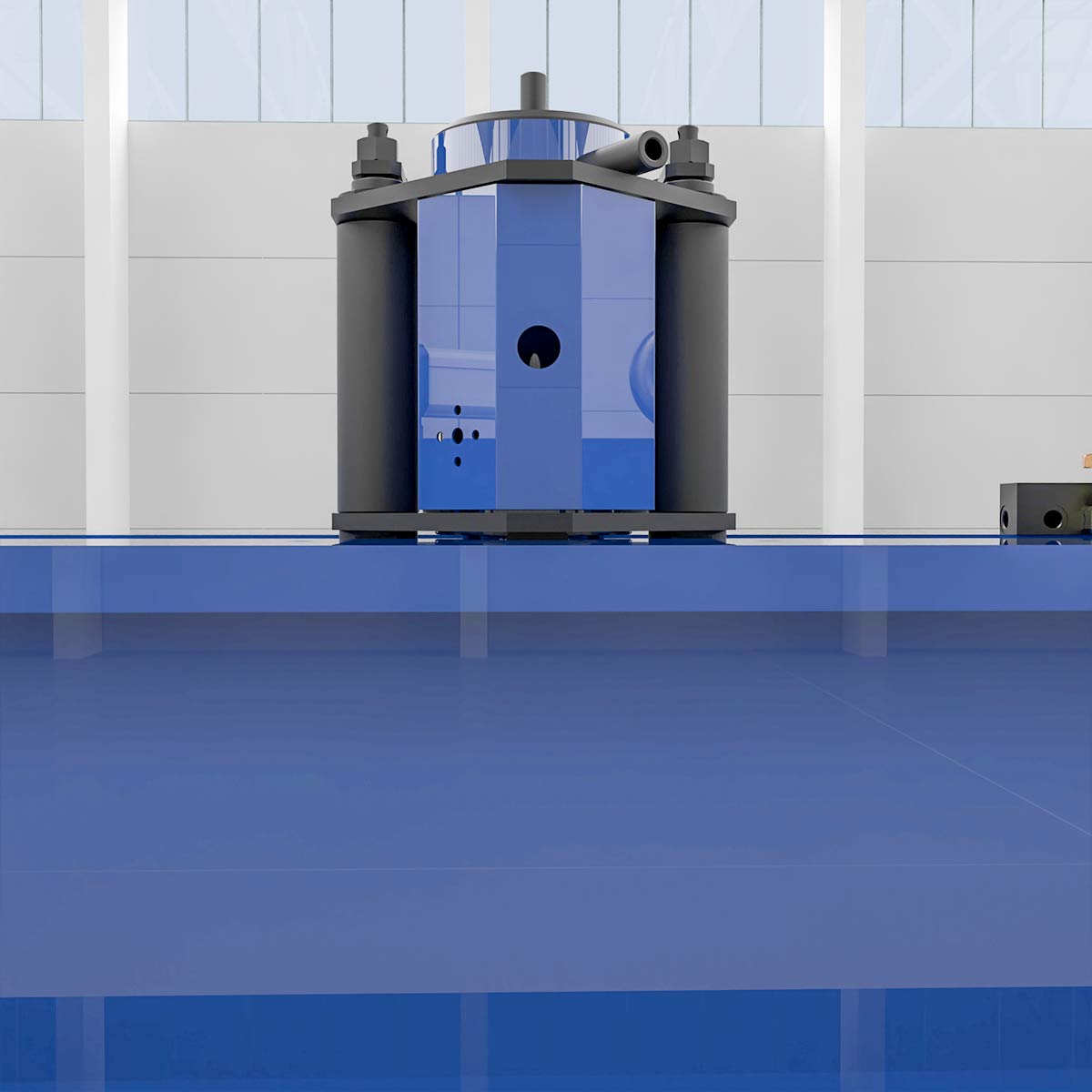

The upper plate slides vertically by hydraulic actuation on the four guide columns and can be overturned 360° through reduction gears. The upper plate clamping in the exact horizontal position depends on the four hydraulic actuated locating pegs.

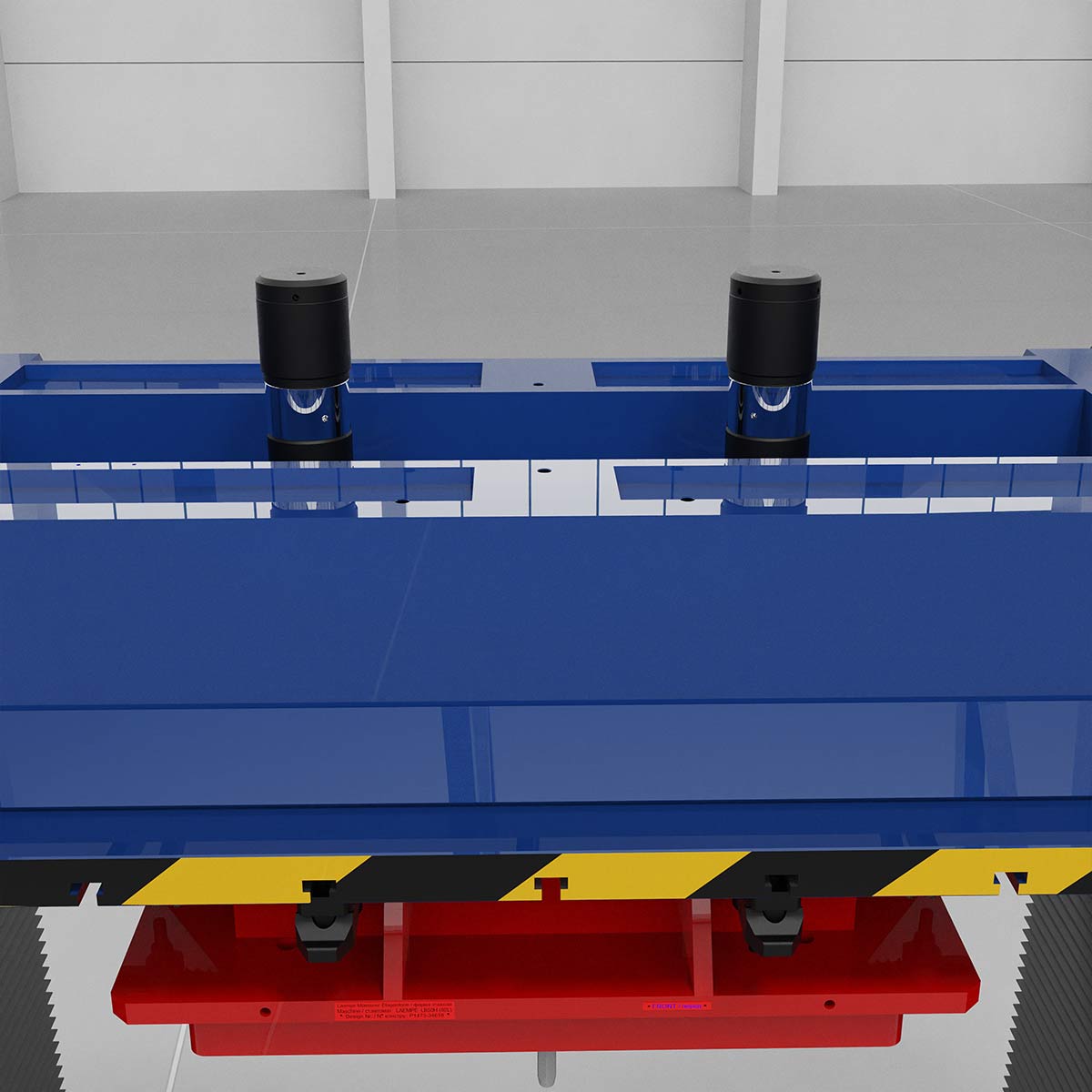

The lower plate is hydraulically extensible, sliding on the base guided by ball bearings. It allows to draw the lower part of the die or mould out of the press into an effortless working position.

All functions are comfortably performed from the control panel.

STANDARD MOVEMENTS OF THE PLATENS

The upper plate slides vertically by hydraulic actuation on the four guide columns and can be overturned 360° through reduction gears. The upper plate clamping in the exact horizontal position depends on the four hydraulic actuated locating pegs.

The lower plate is hydraulically extensible, sliding on the base guided by ball bearings. It allows to draw the lower part of the die or mould out of the press into an effortless working position.

All functions are comfortably performed from the touch panel.

VIDEO

FEATURES

Structure

- Press with 4 chrome-plated alloy steel columns, structures made of welded and normalized steel, nd a sturdy cast iron baseplate to guarantee high rigidity and bending resistance.

- Basement embedded in a robust arc-welded structure, that is highly rigid and flexion-proof

- 2 hydraulic cylinders for the upper plate actuation guarantee an optimal distribution of surface pressure.

- Easy clamping force setting, by means of the touch panel.

- Room-saving arrangement of the hydraulic power unit with considerable noise reduction in press upper part.

- The hydraulic power unit can be easily and safely reached by means of a specific ladder.

- Very long maintenance-free press ram precision guides, with bronze bushings lubricated for life with teflon coating

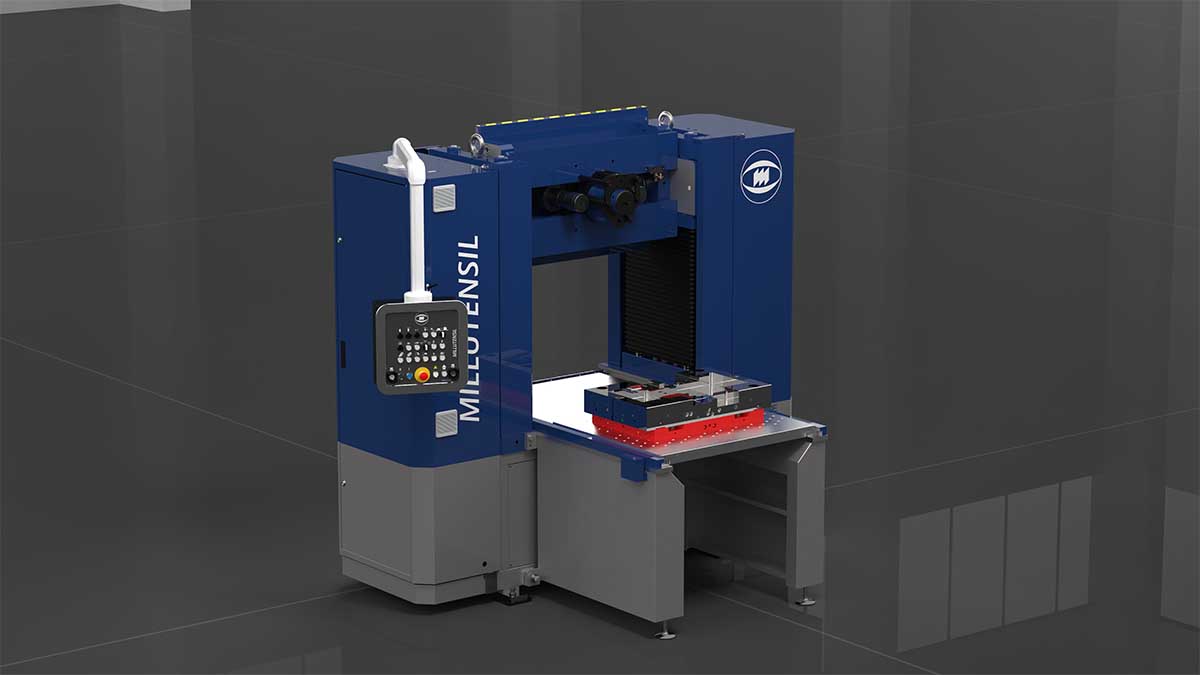

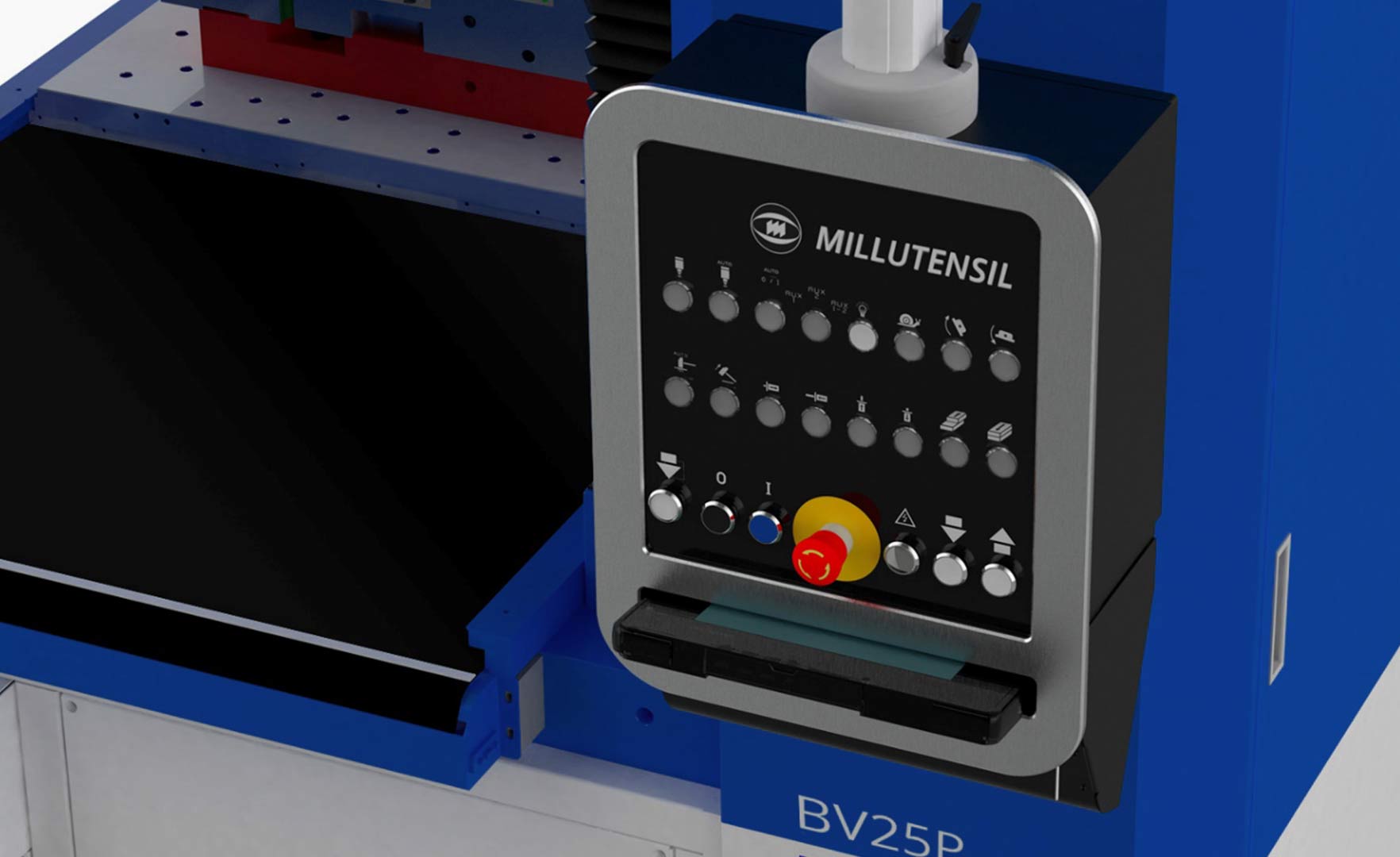

CONTROL PANEL

CONTROL PANEL

Both models are equipped with a control panel with manual buttons and user-friendly graphic icons to simplify the use of the spotting press. All working movements and functions of the press are graphically represented.

Two-hands command.

Due to security reasons, some functions can be activated only through traditional buttons (i.e. downstroke must be carried out with two-hands, in compliance with EU-UL-CSA safety legislation).

The control panel is mounted suspended on the press right side and can also be rotated to the back so that it is even easier to use for the operator.

In the pulpit station a new Siemens multi-touch ITP 1000 can be embedded (OPTIONAL).

This new Siemens multi-touch ITP 1000 is supported by a dedicated app called MyMILL© App, that has been developed by Millutensil as a result of the ongoing cooperation between Millutensil and their customers.

EQUIPMENTS FOR THE PRESS

green mode

By means of a special low-pressure circuit, oil is sucked from the tank. This allows a higher speed, without heating the oil, with a definitively low energy consumption.

After 100 seconds out of service, the hydraulic unit turns off in order to save energy. By pressing the specific push-button, the group is activated and hydraulic pressure is immediately restored.

OPTIONAL EQUIPMENTS FOR THE MOULDS

Hydraulic ejection unit

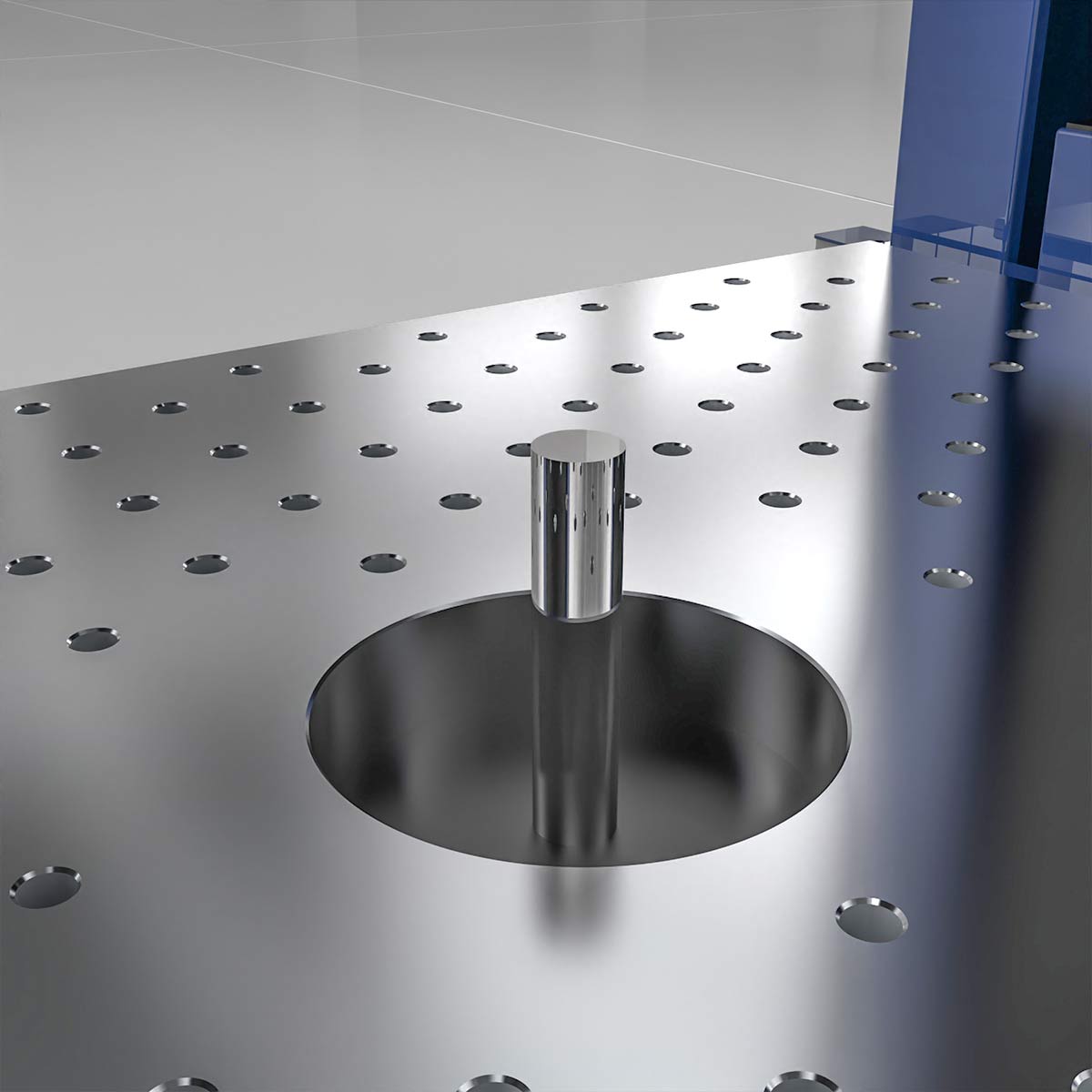

Hydraulic ejector cylinder in the lower plate (option)

The ejection unit initiates the movement of the ejection pins of dies and moulds for plastic materials and die casting.

This utility is made up of a hydraulic cylinder located in the middle of the press basement.

It allows to check and test some important mould functions in a very short time.

The pressure / thrust force is set by means of the il touch panel. The operating pressure depends directly on the line pressure. The advantage is the sensitive test of the mould ejection systems.

ENERGY ACCUMULATOR

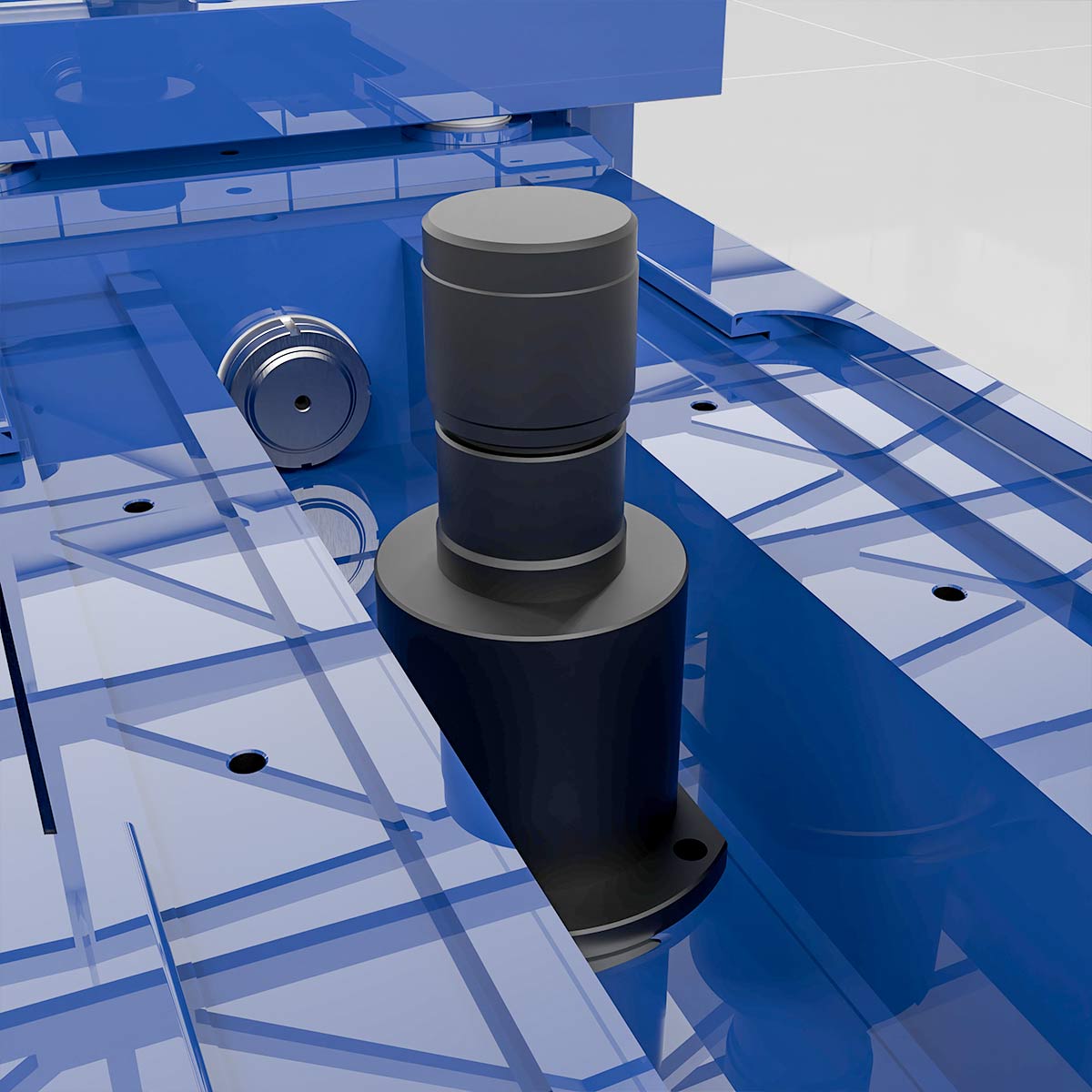

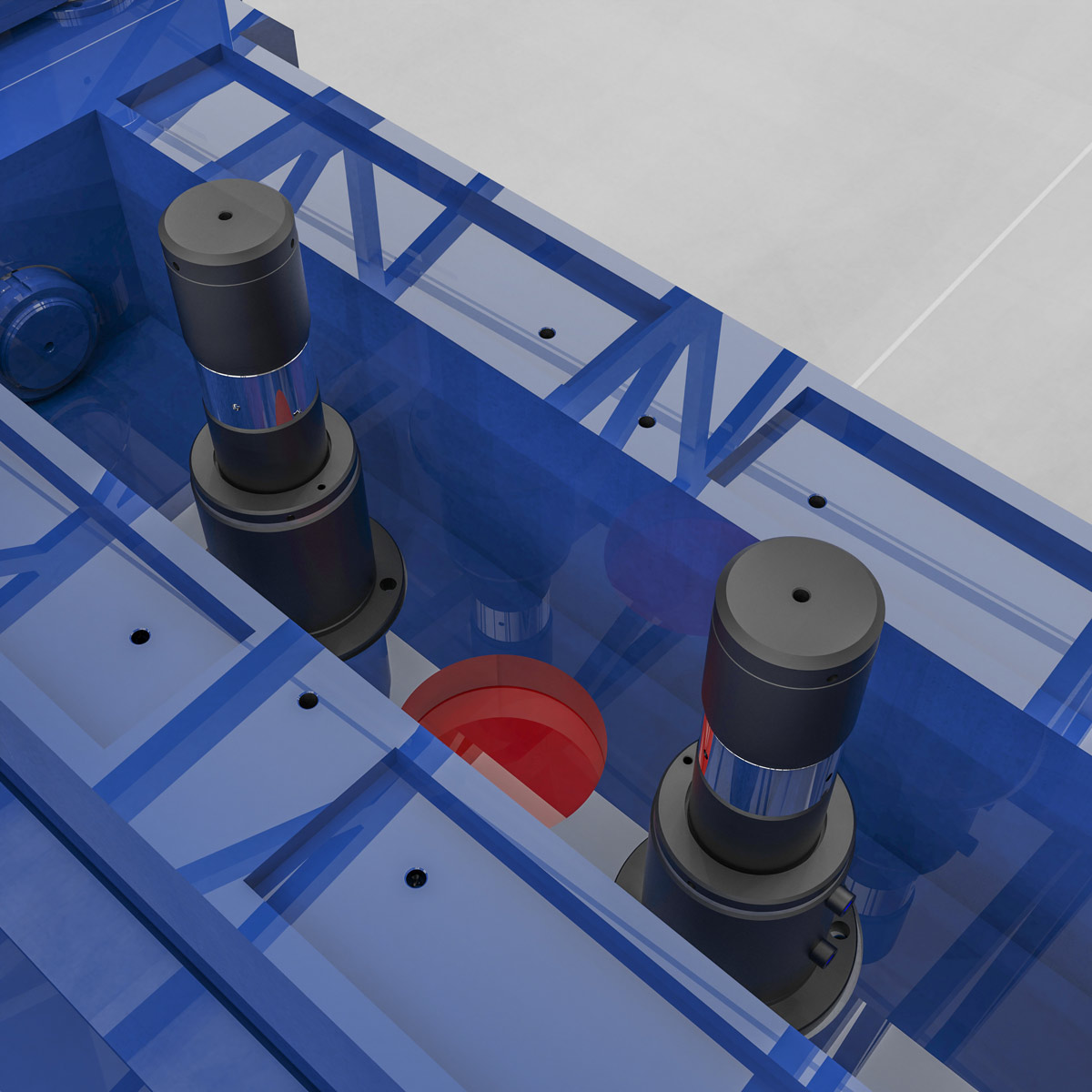

Patented single shot energy accumulator

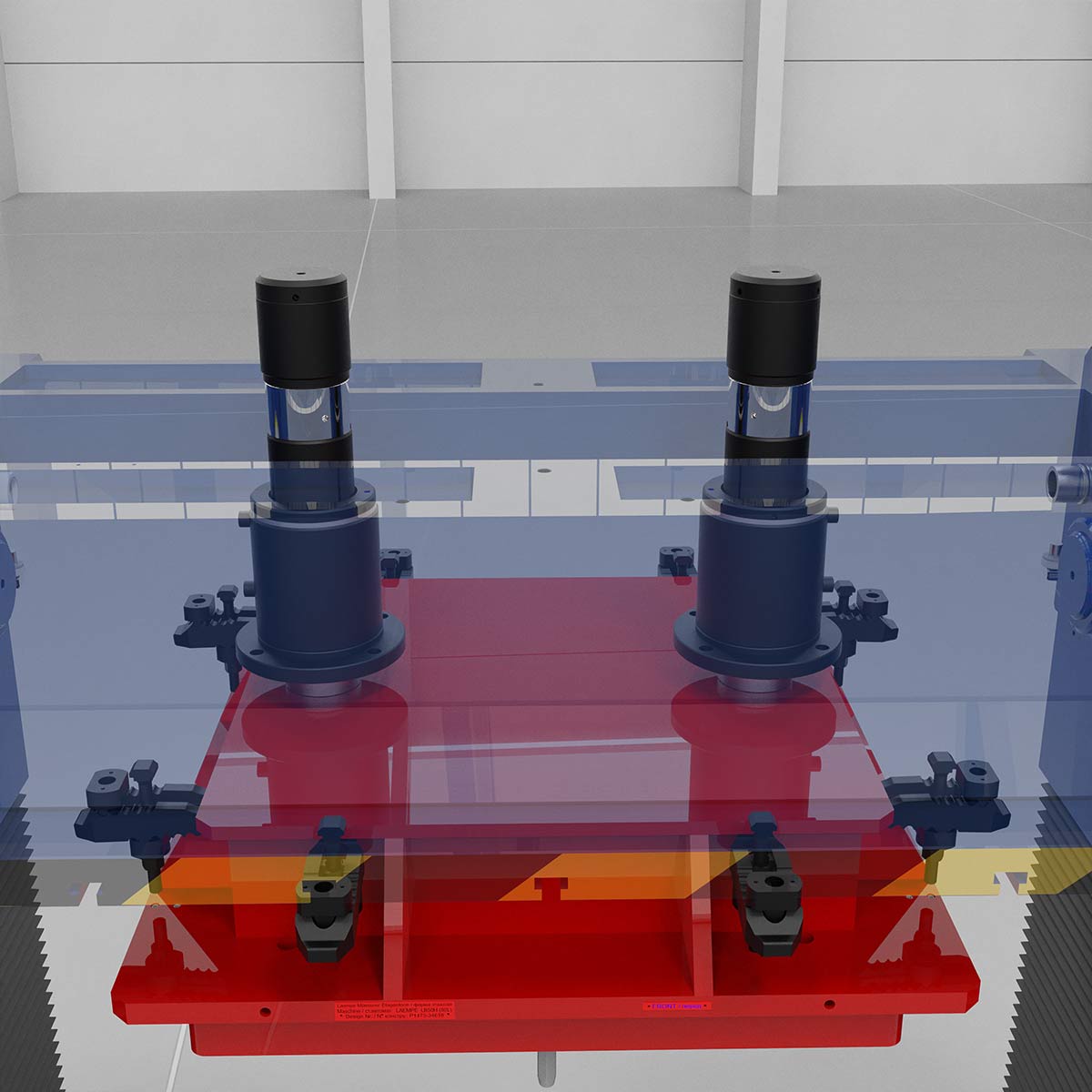

This optional device is indispensable to set up dies and moulds for plastic materials and die casting. This exclusive Millutensil accessory is made one (BV 25P) or two (BV 26C) mechanical devices with hydraulic start-up assembled on the upper plate of the press.

Compression springs are loaded by means of hydraulic pressure. Their dynamic action creates micro-vibrations that, applied at the same time with the press clamping force, increases the efficiency of the Prussian blue marking. The advantage of using the single shot energy accumulator is that the final trail on the mould is straightforward as the surface sections to be improved are clearly displayed. Not to mention that production and manual adjustment costs are also cut.

This system is applied at the end of the die & mould spotting process with the highest possible pressure. It acts on the closed mould without causing any inconvenient to it and to the press structures.

The dynamic action of this device is independent from the press clamping movement. As a consequence, the dynamic action of the energy accumulator will be coupled with the press clamping force.

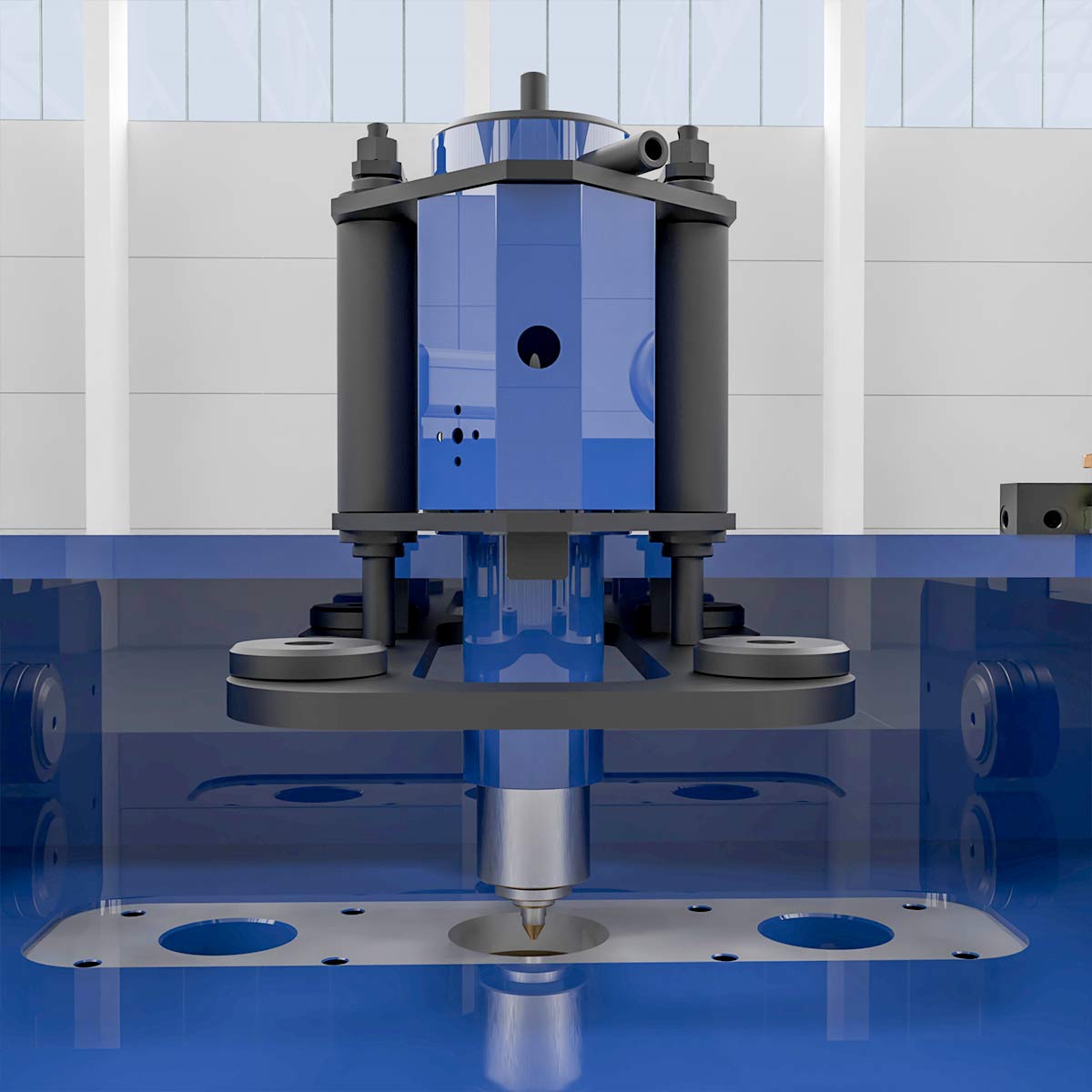

Automatic special wax injection unit

The final mould quality trial can be performed by a low-pressure wax injection. It provides a way to inject special wax at a low pressure into the mould cavity.

In this way, mould makers can check dimensions and thicknesses of pre-production mouldings (even the thinnest flash) to ensure the correct filling. The wax injection unit includes: wax container with electric heating, pneumatic action with air pressure control and temperature control of the chamber to attain constant wax fluidity.

The injection unit is easy to access as it is placed on top of the ram. The electric heating temperature is set through a knob and adjusted with a thermostat.

For an easy mounting, the device can be moved transversally and longitudinally, and then fastened.

The injection function is activated directly on the control panel. Injection is performed using compressed air with an operating pressure equal to Max 6 bar. Usually the wax has a recede factor of 0,6% and it can be used up to 4/5 times.

Upon request customized injector can be tailor designed with 20 bars Max pressure with disposable wax. On the display panel the injection timing is displayed. The use of hot channel systems excludes the use of the wax injection unit.

TECHNICAL DATA

| Description | BV 25P | BV 26C | |

| – Size of press plates | mm | 770 x 660 | 980 x 750 |

| – Max. clamping force | kN | 180 | 300 |

| – Max. opening force | kN | 150 | 250 |

| – Max. load capacity on lower plate | kg | 2500 | 4000 |

| – Max. load capacity on upper plate | kg | 800 | 1200 |

| – Min. – max. opening between plates | mm | 230 – 760 | 320 – 920 |

| – Distance between columns | mm | 900 | 1090 |

| – Upper plate approaching speed | mm/sec | 25 | 20 |

| – Upper plate working speed | mm/sec | 6 | 6 |

| – Power of main motor | kW | 4 | 5,5 |

| – Machine weight | kg~ | 2600* | 3800* |

Other solutions

BV E SERIES

Three models available depending on the platen dimensions, (980×750 mm / 1.200×1.000 mm / 1.500×1.000 mm) with a hydraulic system controlled by electronic servo proportional valves and a control of parallelism through Heidenhain optical lines.

All models are equipped with user-friendly graphics touch control panel.

The E series presses are offered with option -R, -G or -RG version and can also be equipped with all optional accessories.

BV 32E – 33E – 34 – 35 E

The BV 32E – 33E – 34 and 35 E are the advanced version with a hydraulic system controlled by electronic servo proportional valves and a control of parallelism through two specific linear encoders.

All models are equipped with user-friendly graphics touch control panel

Platen dimensions are 1.600×1.300mm or 2.000×1.500 mm.

As all E series, the BV 32/33/34/35 E series presses are offered with option -R, -G or -RG version and can also be equipped with all optional accessories.

Our worldwide references